Mechanical engineering is one of the most versatile and widely pursued engineering fields. With an endless range of career paths, it allows students to explore everything from robotics and automotive design to renewable energy, aerospace, and smart technologies like the Internet of Things. It’s a dynamic field that opens up countless possibilities for those passionate about innovation and problem-solving.

If you love turning ideas into real-world products and bringing designs from concept to completion, mechanical engineering might just be your ideal path. As a mechanical engineer, you’ll need to understand how forces, materials, and environments impact your designs—and how to craft solutions that meet those challenges head-on.

This blog guides students and aspiring engineers through what mechanical engineering entails, the kind of work involved, and the exciting problems mechanical engineers tackle every day.

What is Mechanical Engineering?

Mechanical engineering is one of the broadest, most dynamic fields in modern engineering. It’s the backbone of innovation, shaping the world around us in ways you might not always notice. Mechanical engineering is the branch of engineering that applies principles of physics and materials science to design, build, and maintain machines and systems.

It’s also a field that touches nearly every industry. Whether it’s automotive, aerospace, robotics, energy, or healthcare, mechanical engineers are everywhere, solving problems, creating solutions, and driving progress. In fact, according to the U.S. Bureau of Labor Statistics, mechanical engineering remains one of the most in-demand engineering disciplines, with employment opportunities projected to grow by 7% over the next decade.

What Do Mechanical Engineers Do?

At their core, mechanical engineers are problem solvers. They apply scientific knowledge to develop practical solutions for real-world problems. Whether it’s designing a more efficient engine, developing cutting-edge medical devices, or creating sustainable energy systems, mechanical engineers are constantly innovating.

Their expertise isn’t just limited to one area—these professionals work across industries, contributing to everything from manufacturing and automotive to aerospace, healthcare, and energy.

Take a look at a few key tasks mechanical engineers often tackle:

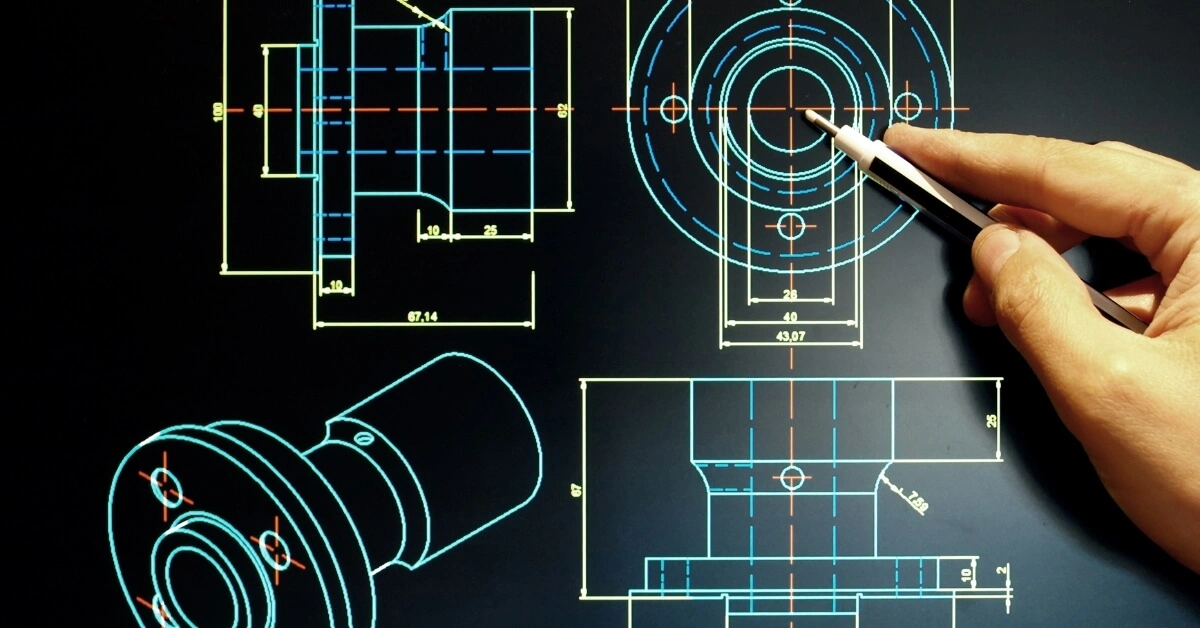

Design and Development

They’re involved in designing mechanical systems and products, often using CAD (computer-aided design) software to create 3D models. These models help engineers visualize their designs and make necessary modifications before moving to production.

Testing and Validation

After designing a product, engineers perform rigorous testing to ensure it meets the required specifications. They use simulation tools to predict how the system will behave in real-world conditions.

Problem-Solving

Engineers often find themselves identifying inefficiencies in existing processes or systems and brainstorming ways to make improvements. For example, they might develop an engine that uses less fuel while maintaining the same level of performance, which is critical in today’s push for sustainability.

Core Mechanical Engineering Services

Mechanical engineering firms provide a wide array of services to help businesses meet their goals. These services are often customized to meet specific project needs, making them invaluable for companies seeking to develop new products or optimize existing ones.

1. Design and Development

Mechanical engineers play a crucial role in product design and development. They use advanced tools to turn ideas into reality. For instance:

- CAD/CAM Software: This software allows engineers to create precise 3D models of parts and systems. These models provide the foundation for detailed product development and manufacturing instructions.

- Product Design & Prototyping: Engineers are involved from the very beginning, helping to conceptualize new products or improve existing ones. A great example is the development of electric vehicles, where engineers continuously work on enhancing battery efficiency, motor performance, and vehicle aerodynamics.

- 3D Printing and Rapid Prototyping: Thanks to innovations like 3D printing, engineers can quickly produce prototypes, test them, and make improvements without needing expensive molds or tools. This speeds up the product development cycle significantly.

2. Analysis and Simulation

Testing products in the real world can be time-consuming and expensive. That’s why mechanical engineers rely heavily on advanced simulation tools to predict how systems will perform under different conditions. Some common tools include:

- Finite Element Analysis (FEA): FEA allows engineers to simulate the behavior of materials under stress. For example, in the automotive industry, FEA helps predict how a car frame will react in a crash, which is crucial for safety.

- Computational Fluid Dynamics (CFD): CFD is used to analyze how fluids (like air or water) move around objects. In aerospace, engineers use CFD to minimize drag on aircraft wings, improving fuel efficiency and reducing costs.

- Structural Analysis: Structural integrity is crucial in industries like aerospace and construction, where safety is non-negotiable. Engineers use structural analysis to evaluate the durability and performance of materials, ensuring they won’t fail under stress.

3. Testing and Validation

Mechanical engineers don’t just design products—they rigorously test them to ensure they work as intended:

- Material Testing: Engineers evaluate materials like metals, plastics, and composites to ensure they meet the necessary strength and durability standards. In aerospace, for example, materials must be light yet strong enough to withstand extreme conditions.

- Performance Testing: Performance testing allows engineers to see how a system operates under real-world conditions. This is especially important in industries like automotive, where safety and reliability are critical.

- Failure Analysis: When things go wrong, engineers perform failure analysis to determine the root cause and recommend corrective actions. This is crucial for avoiding future issues and improving product reliability.

4. Manufacturing and Fabrication

Mechanical engineers also oversee the manufacturing process, ensuring that products are built to specification:

- Machining: This involves removing material from a workpiece to create the desired shape. Precision is key here, as even a small mistake can lead to a faulty product.

- Welding: Engineers also oversee welding processes, ensuring that metal parts are joined securely. This is especially important in industries like automotive and construction, where weak welds can lead to catastrophic failure.

- Assembly: Finally, engineers ensure that all components are assembled correctly to form the final product. This step often involves quality control checks to ensure everything fits together as it should.

Specialized Mechanical Engineering Services

Mechanical engineers also offer specialized services that cater to specific industries and applications:

1. Thermodynamics and Heat Transfer

Mechanical engineers use their knowledge of thermodynamics to design systems that manage heat transfer, which is essential for many industries:

- HVAC Systems: Engineers design efficient heating, ventilation, and air conditioning systems to ensure comfortable indoor environments. In large buildings, this can lead to significant energy savings.

- Energy Efficiency: Engineers also develop energy-efficient systems, from HVAC units to entire power plants, helping companies reduce costs and meet environmental regulations.

- Refrigeration: Refrigeration systems are essential in industries like food processing and pharmaceuticals, where maintaining precise temperature control can mean the difference between a safe product and a spoiled one.

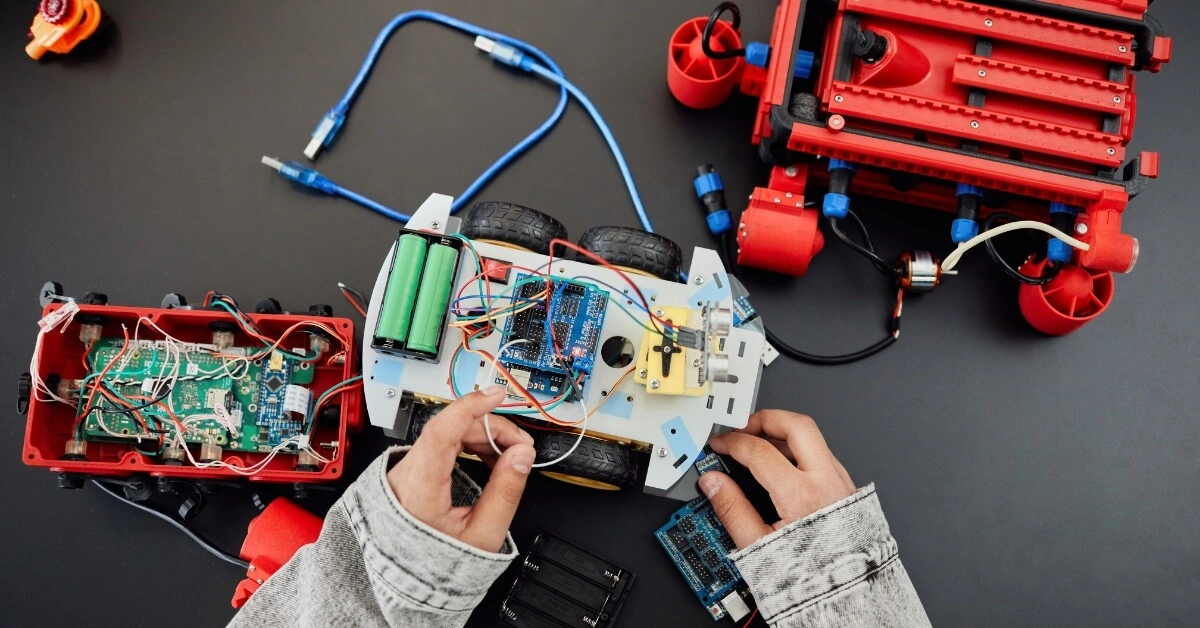

2. Robotics and Automation

In today’s manufacturing world, automation is key to staying competitive. Mechanical engineers help implement automation systems and robotics to increase productivity:

- Industrial Robots: From assembling cars to packaging goods, industrial robots are becoming more common. Engineers design these robots to handle tasks with speed and precision, improving efficiency.

- Automation Systems: Engineers create automated systems that streamline processes, reduce errors, and improve safety. This is especially useful in industries like logistics and manufacturing.

- Mechatronics: Mechatronics is a multidisciplinary field that blends mechanical, electrical, and software engineering. Engineers in this field develop sophisticated systems like autonomous vehicles and surgical robots.

3. Biomedical Engineering

Mechanical engineering isn’t just about machines. In the healthcare industry, it plays a vital role in developing life-saving technologies:

- Medical Devices: Engineers design and test everything from artificial limbs to MRI machines. Their expertise ensures that medical devices are safe, effective, and reliable.

- Prosthetic Limbs: Engineers are constantly improving the design and functionality of prosthetic limbs, helping people regain mobility and independence.

- Biomechanics: Biomechanics applies mechanical principles to biological systems. For instance, engineers may study how the human body moves to improve the design of athletic gear or rehabilitation devices.

4. Sustainable Engineering

As the world moves towards a more sustainable future, mechanical engineers are at the forefront of developing eco-friendly technologies:

- Renewable Energy: Engineers are involved in designing wind turbines, solar solutions, and other renewable energy systems. Their work is essential for reducing reliance on fossil fuels.

- Green Technologies: Engineers are developing technologies that reduce environmental impact, such as electric vehicles and energy-efficient appliances.

- Environmental Impact Assessments: Mechanical engineers also help companies evaluate the potential environmental impact of their projects, ensuring they meet regulatory standards.

The Value of Hiring a Mechanical Engineer

Hiring a skilled mechanical engineer can be a game changer for your business. Here’s why:

- Improved Product Quality: Engineers ensure your products are designed to the highest standards of quality and reliability.

- Increased Efficiency: By streamlining processes and improving designs, mechanical engineers help you reduce waste and lower costs.

- Reduced Risk: Engineers can identify potential problems before they become major issues, reducing the risk of costly failures.

- Innovation: Whether it’s developing a new product or improving an existing one, mechanical engineers are always pushing the boundaries of what’s possible.

- Compliance with Regulations: Engineers ensure your products meet all relevant safety and performance standards, helping you avoid fines and legal issues.

Choosing the Right Mechanical Engineering Firm

When it comes to choosing a mechanical engineering firm, not all companies are created equal. Here are a few tips to help you make the right choice:

- Experience and Expertise: Look for a firm with a proven track record in your industry. An experienced team will be better equipped to handle complex challenges.

- Portfolio: Ask to see the firm’s portfolio of past projects. This will give you a sense of their capabilities and whether they’re a good fit for your needs.

- References: Don’t hesitate to ask for references from previous clients. This will give you insight into the firm’s communication skills, reliability, and professionalism.

- Communication: A good engineering firm will keep you in the loop throughout the entire process, ensuring your project stays on track and meets your expectations.

- Cost: While cost is important, it shouldn’t be the only factor in your decision. Sometimes, it’s worth paying a little extra for a higher level of expertise and service.

How Much Do Mechanical Engineers Make?

Mechanical engineering is a well-paid field with strong job prospects. According to the U.S. Bureau of Labor Statistics, the average salary for mechanical engineers in 2020 was $95,300 per year. This can vary based on factors like experience, industry, and location.

Final Thoughts

Mechanical engineering is like the invisible hand behind so many of the things we rely on daily, from the cars we drive to the technologies that power our homes. It’s a field packed with innovation, creativity, and problem-solving, touching industries as diverse as healthcare, aerospace, and renewable energy. Mechanical engineers don’t just design machines—they create solutions that shape our world for the better.

At NTI Engineering, we pride ourselves on delivering high-quality mechanical engineering services that help businesses thrive. Whether you need design assistance, testing, and validation, or help with manufacturing, we’re here to turn your vision into reality.